A62R

A62R

Working Height:

Horizontal Outreach:

Capacity:

MANITEX A62 - Non-CDL

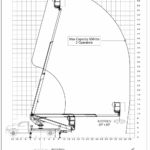

62 feet

38 feet

2 men, 550 lbs

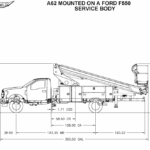

62’ Bucket Truck mounted on a Class 5 Chassis.

Mounted on various chassis options including, Ford, Dodge, and Chevy. Available with either a steel service body or a flatbed.

- Capacity: 550 lbs

- Max Working Height: 62 feet

- Type of Articulation: Telescopic

- Number of Boom Sections: 3 Boom

- Boom Angle: -15° / + 75°

- Chassis Requirements GWVR: 15,400 lbs

- FAWR (lbs): 7,000 RAWR: 14,700 lbs

- Max Height floor of bucket: 56 feet

- Outreach: 38 feet

- Front Outrigger: Fixed A Shape

- Rear Outrigger: Fixed A Shape

- Hoses and cables: Inside booms

- Cylinder of extension: Inside booms

- Position and angle control: Yes

- Size of basket: 67 x 28 x 43 Inches [aluminum]

- Start-up and shutdown of the main engine and any auxiliary engine from the basket

- Protective sidebars

- Protection on controls area on column and basket

- Acoustic device for PTO plugged in

- A self-locking device on rotation

- Warning device operating outriggers (truck dashboard)

- Interlock for stabilizers

- Hand pump for emergency lowering

- Document folder on the basket

- Thermal protection on the electrical system

- Emergency button with stop engine device

- Hydraulic basket rotation

- Holding valves on every cylinder

- Maximum pressure valves on the hydraulic circuit

- Use and maintenance manual

- Jiblet Winch with 200 lbs max capacity

- 110V Electrical outlet in the basket and a 2.2 kW inverter

- Various body options including service body and flatbeds

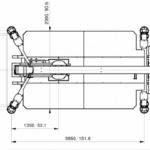

BASE FRAME

Steelsubframe bolted to truck's chassis. Equipped with 4 stabilizers with direct deployment.

The front part of the frame is fitted with the attachment plate.

Service body and the flatbed also features an anti-slip floor as standard.

ROTATIONAL TURRET

The turret is powered by hydraulic swing motor, and includes manual control station at base-of-turret and has ±355° degrees of rotation to either side .

BOOM

The boom is telescopic with hydraulic extension.

The boom has an operating range of -15° a +75 ° to the horizontal.

Self lubricating slide pads for minimal maintenance.

The boom design makes the machine extremely rigid while saving on weight.

All internal hose routing protects the hydraulic hoses and electrical cables from damage.

OPERATOR BASKET

Equipped with an 2 man aluminum basket with 550 lbs of capacity and measures 67 x 28 x 43 inches. Standard safety pedal is installed to activate the aerial controls from the basket. Basket is also equipped with 2 anchor points for safety harnesses. ±90° of rotation is standard to increase efficiency.

BASKET LEVELLING

It is ensured by a closed-loop hydraulic master / slave system with manual resynch.

CONTROLS

Equipment features a compensated proportional hydraulic control system that can control several movements at the same time. Stabilization with distributor featuring 4 independent levers to separately control the 4 stabilizers independently.

Upper structure controls available from either the ground controls station or the basket.